The packaging industry is experiencing unprecedented growth, driven by e-commerce booms, sustainable packaging demands, and the continuous need for faster, more efficient production. At the heart of this progress lies reliable and precise motion control, largely powered by gear motors. Selecting the right gear motor model for packaging equipment is a critical decision, directly impacting production speed, product quality, and overall operational costs. However, many enterprises stumble on common pitfalls during the purchasing process. This article outlines those mistakes and offers practical solutions, ensuring a smoother and more profitable investment.

The Growing Demand and Importance of Gear Motors in Packaging

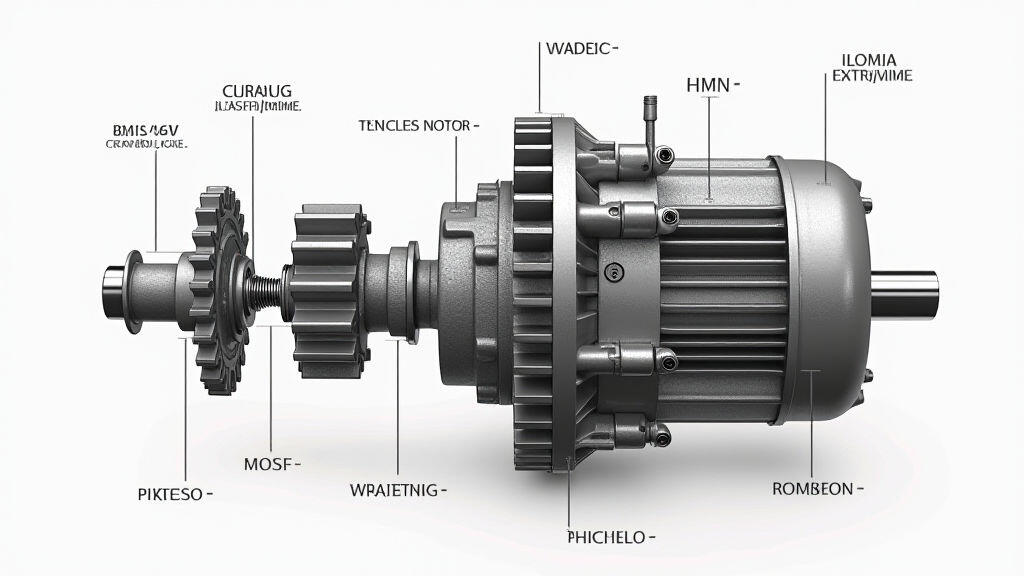

Before diving into the challenges, let's understand why gear motors are so crucial. Packaging machinery relies on precise movements for tasks like filling, sealing, labeling, conveying, and wrapping. Gear motors provide the necessary torque and speed reduction to power these operations accurately. Modern packaging machines often incorporate complex robotic systems, further amplifying the importance of selecting durable, efficient, and responsive gear motors. The rise of flexible packaging – driven by consumer demand for eco-friendly options and customized designs – presents new demands on machinery, putting additional stress on motor systems. This necessitates a deeper understanding of motor specifications beyond simple horsepower ratings.

Mistake #1: Focusing Solely on Price – Ignoring Total Cost of Ownership (TCO)

One of the most frequent errors is prioritizing the lowest initial price. While budget is undoubtedly a factor, neglecting the long-term cost of ownership is a short-sighted strategy. A cheaper gear motor might have a shorter lifespan, require more frequent maintenance, or consume more energy.

Mistake #2: Lack of Detailed Application Analysis

Blindly selecting a gear motor based on general application needs is a recipe for problems. Every packaging task has specific requirements like torque, speed, accuracy, load capacity, and environmental conditions. Ignoring these factors leads to under- or over-specifying the motor.

Mistake #3: Neglecting Gear Ratio and Efficiency Considerations

The gear ratio determines the speed reduction and torque amplification provided by the motor. Choosing the wrong gear ratio can result in inefficient operation or insufficient power for the intended task. Similarly, motor efficiency significantly impacts energy consumption and operational costs. Aging motors are notorious for significant efficiency drops.

Mistake #4: Ignoring Environmental Factors and Operating Conditions

Packaging environments can be harsh, with exposure to dust, moisture, chemicals, and extreme temperatures. Selecting a motor not properly rated for these conditions can lead to premature failure and costly repairs.

Mistake #5: Overlooking Maintenance and Support

A high-quality gear motor is only as good as its maintenance and support. Lack of access to spare parts, technical assistance, and qualified service technicians can significantly impact uptime and productivity.

Mistake #6: Insufficient Vibration and Noise Analysis

Packaging machines often operate in close proximity to human workers. Excessive vibration and noise from the gear motor can create a disruptive and potentially hazardous environment.

The Future of Gear Motors in Packaging: Towards Smart and Sustainable Solutions

The packaging industry is trending towards smart factories and sustainable practices. This puts new demands on gear motors, requiring greater precision, efficiency, and reliability. Future advancements focus on:

Conclusion

Selecting the right gear motor for packaging equipment is a complex process. By avoiding these common mistakes and implementing the solutions outlined above, packaging enterprises can ensure a reliable, efficient, and cost-effective investment. The future of packaging hinges on automation and technological advancements, and the gear motor remains a vital component in achieving these advancements. The convergence of IIoT, energy efficiency, and advanced materials is ushering in a new era of smart and sustainable gear motor solutions, offering unprecedented opportunities for packaging companies to optimize their operations and maintain a competitive edge. Companies like MES-Drive are at the forefront of this innovation, providing cutting-edge gear motor technology and comprehensive support to meet the evolving needs of the packaging industry. As demand for faster, more sustainable, and more adaptable packaging solutions continues to grow, the importance of intelligent gear motor selection will only increase.

Leave A Reply

Your email address will not be published. Required fiels are marked